Case Study – Surgical Lamp Housing

Project Overview

A large international manufacturer of durable medical equipment engaged EnTech Plastics to develop a plastic housing for a surgical lamp.

The design included two injection molded components which were assembled together and then over molded with a ‘soft touch’ thermoplastic rubber to allow surgery room personnel to move the lamp more easily.

The Challenge

This assembly needed a high end engineering resin to withstand harsh conditions in which it would be used.

- Long term heat resistance of 150° C (300° F)

- Chemical resistance – operating room cleaning and sterilization

- Hydrolysis resistance – operating room cleaning and sterilization

- Dielectric properties – reduce interference with nearby electrical equipment

- Lightweight – ease of use by operating room staff

The Solution

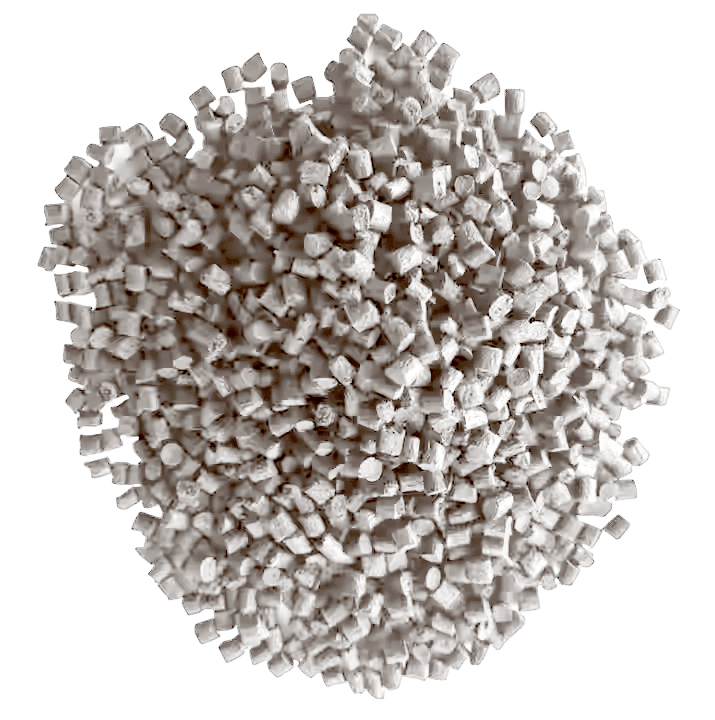

Syndiotatctic Polystyrene (sPS) was chosen because its properties matched the demanding environment that the surgical light would see. sPS is a specialized form of polystyrene where the polymer chains are arranged in a regular, alternating pattern.

This unique structure imparts several key engineering benefits when used in medical lamp housing components:

High Heat Resistance

sPS has a higher melting point and thermal stability compared to many engineered resins. This makes it particularly suitable for applications such as medical lighting systems which can generate significant heat. sPS allows the lamp housing to withstand the prolonged heat generated by medical lamps without warping, discoloration, or degradation.

Dimensional Stability

The crystalline structure of sPS provides excellent dimensional stability. It resists deformation under stress or heat and maintains its shape over time. This is important to ensure that the lamp housing maintains its integrity and precise fit within the surgical light assembly.

Chemical Resistance

Medical lamps undergo frequent cleaning and sterilization. The housing material must resist degradation from harsh chemicals to ensure the longevity of the surgical lamp. sPS offers excellent chemical resistance and is less susceptible to damage from common chemicals, disinfectants, and solvents used in medical environments.

High Strength and Stiffness

For medical lamp housings, strength is important to ensure the housing does not crack or break under mechanical stresses, impacts, or handling during routine use. The crystalline structure of sPS contributes to its mechanical strength and stiffness.

Low Moisture Absorption

Cleaning and sterilization procedures may expose the surgical lamp housing to moisture or water. sPS has low moisture absorption, which makes it resistant to changes in mechanical properties due to humidity or water exposure.

Electrical Insulation Properties

sPS has good electrical insulating properties. It helps to manage the electromagnetic interference (EMI) of the surgical lamp and, because it doesn’t conduct electricity, it reduces possible electrical hazards.

The Summary

This surgical lamp housing project demonstrated both EnTech’s ability to develop highly engineered plastic components and EnTech’s competitive strength in producing large injection molded plastic components in relatively low annual volumes.

If you are looking for a injection molding partner for a similar product, EnTech is here to answer any questions and solve any problems you may have!

Contact us today to learn more.

Be The First to Know!

Enjoying this article? Stay up to date and sign up now to get notified of new news and insights from EnTech Plastics.