Insights From EnTech

EnTech is here to educate and inform. See our blogs below as they begin to collect and help you learn more about the industry we love.

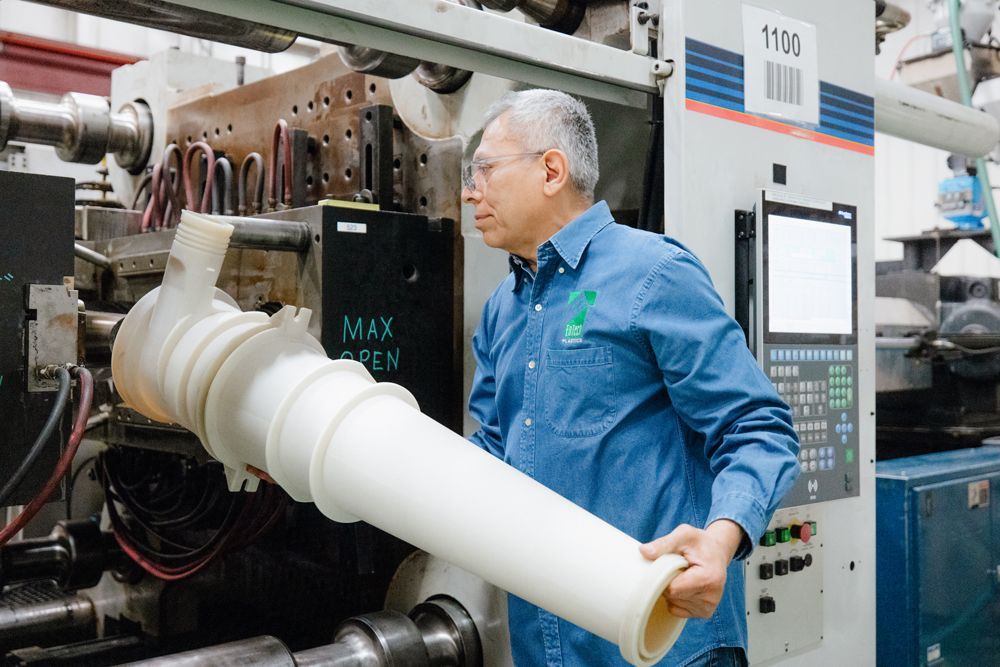

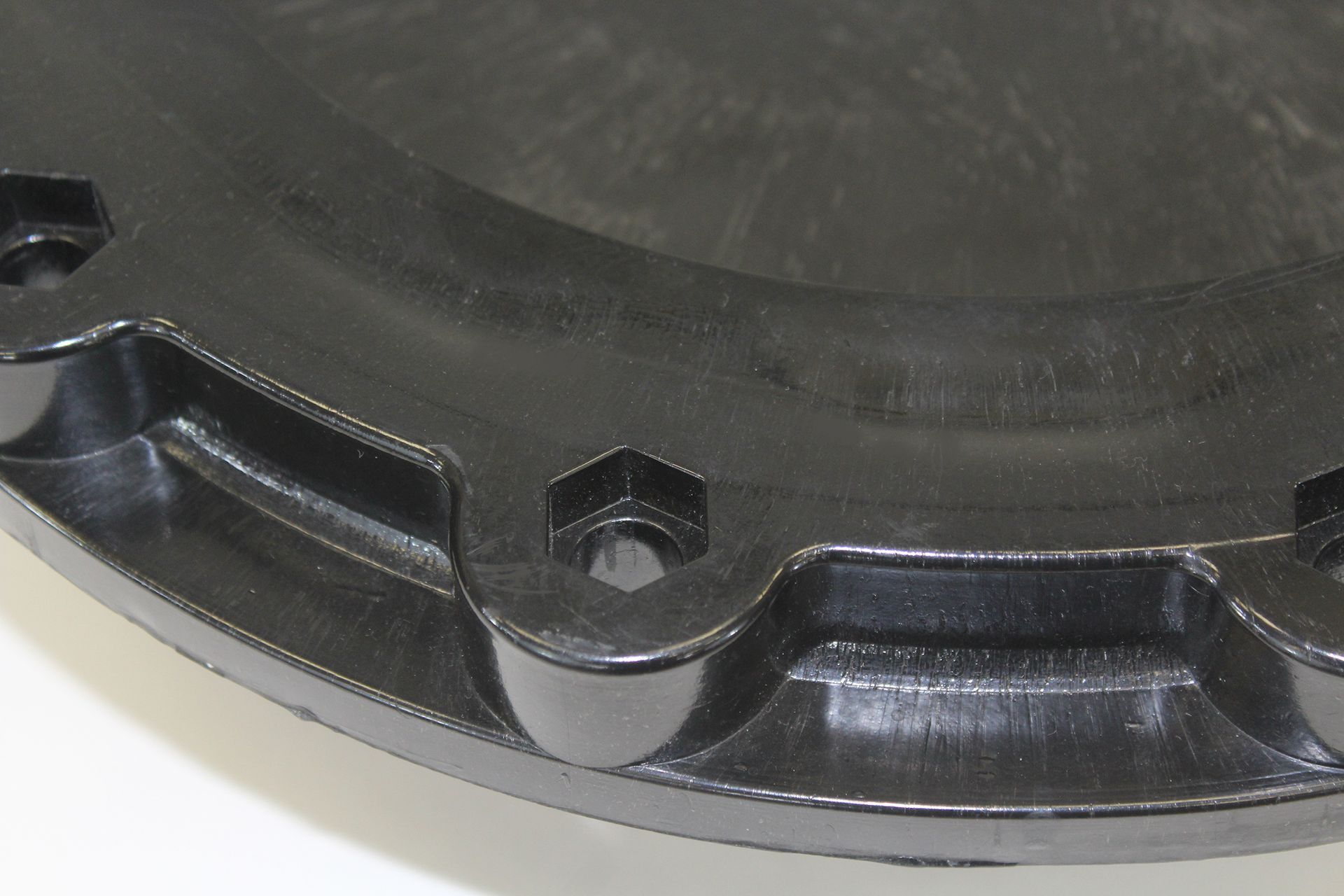

When your design calls for large plastic parts with varying wall thicknesses or complex internal geometries, conventional injection molding often hits its limits. Sink marks appear on thick sections. Warpage compromises dimensional accuracy. Tooling costs skyrocket as you increase tonnage to fill massive cavities. This is precisely where gas assist injection molding technology changes the equation. How Gas Assist Technology Works Gas assist injection molding introduces pressurized nitrogen gas into the mold cavity during the injection cycle. As molten plastic fills the tool, the gas creates hollow channels within thicker sections, pushing the material outward against the mold walls. This process eliminates the heavy core that would otherwise exist in solid parts, while maintaining structural integrity and surface quality. The result? Parts that weigh significantly less, require lower clamping pressures, and exhibit superior aesthetics, all while using the same thermoplastic resins you’d specify for conventional molding. Engineering Advantages for Complex Geometries Gas assist technology excels at solving problems that plague large, complex parts. Consider a structural component with ribs, bosses, and varying wall sections. Conventional injection molding would likely produce visible sink marks in the thick sections of the part. Gas Assist Injection Molding eliminates this issue because the gas channel removes resin in the center of the thick sections so that the wall thickness in the thick sections are similar to the wall sections in the thin sections. We've produced everything from heavy-duty industrial equipment housings to ergonomic medical device enclosures using this process. The technology particularly shines in applications requiring: Tubular or hollow cross-sections without the need for slides or complex tooling actions Components combining structural rigidity with weight reduction, critical in transportation and material handling applications Class A surface finishes on large visible components where aesthetics matter Cost Benefits Beyond the Part The economic advantages of gas assist extend well beyond material savings. Because the gas core reduces the volume of plastic required and lowers the clamping force needed, you can often mold larger parts on smaller, less expensive presses. A part that might require a 1,000-ton machine with conventional molding could potentially run on a 500-ton press with gas assist. Cycle times frequently improve, as well. The gas channels facilitate more efficient cooling in thick sections, reducing the time parts spend in the tool. For low to mid-volume production runs, where tooling amortization significantly impacts piece price, these efficiencies compound into substantial cost reductions. Tool construction costs may decrease, too. Complex parts that would require multiple slides, lifters, or loose cores can sometimes be simplified when gas channels replace solid features. This streamlined approach to tooling means faster builds and fewer potential failure points over the tool’s lifespan. Design Considerations for Success Gas assist molding isn’t a universal solution, but it’s remarkably versatile when applied thoughtfully. Successful implementation requires close collaboration between part designers and molding engineers from the earliest stages. Wall thickness ratios matter significantly. The technology works best when gas channels can form in sections at least 1.5 to 2 times thicker than adjacent walls. Gas penetration length, channel diameter, and injection timing all require precise engineering to achieve optimal results. Resin selection plays a crucial role, as well. While most thermoplastics are compatible with gas assist, engineered resins like glass-filled nylons, polycarbonates, and ABS deliver exceptional performance in structural applications. Material flow characteristics influence how uniformly the gas penetrates and how consistently hollow channels form. Making the Technology Work for Your Application At EnTech Plastics, we approach gas assist projects with the same engineering rigor we apply across all our advanced molding processes. Our team evaluates each design for gas assist feasibility during the quoting phase, identifying opportunities to optimize part geometry, reduce weight, and improve manufacturability. Whether you're developing a next-generation industrial component or refining an existing design for better performance and lower cost, gas assist injection molding might be the solution that transforms complexity from a constraint into a competitive advantage. Ready to explore whether gas assist technology fits your application? Contact our engineering team to discuss your specific requirements and discover how advanced injection molding processes can bring your most challenging designs to life.

Every production run tells a story, and sometimes, that story involves parts that don't quite meet specifications. Whether you're dealing with warped components, surface defects, or dimensional inconsistencies, injection molding quality issues can disrupt your operations and strain your bottom line. The good news? Most molding defects follow predictable patterns, and with the right diagnostic approach, they're solvable. Let's walk through a systematic troubleshooting framework that transforms problem parts into perfect components. Understanding the Root Cause: Beyond Surface-Level Fixes When quality issues emerge, the instinct is often to adjust machine parameters immediately. But rushing to solutions without proper diagnosis can create new problems or mask underlying issues. Effective troubleshooting requires understanding the relationship between four critical variables: Material properties – How the resin responds to heat, pressure, and cooling Tool design – Gate location, venting, cooling channel efficiency Process parameters – Temperature, pressure, injection speed, and cycle time Machine capability – Tonnage, shot size, and control precision Quality defects rarely stem from a single source. Instead, they emerge from the interaction between these elements; this is why systematic diagnosis beats guesswork every time. Common Defects and Their Diagnostic Pathways Warpage and Dimensional Instability Parts that twist, bow, or fail to hold tolerances point to uneven cooling or internal stresses. Start by examining cooling channel performance—are all areas of the tool reaching uniform temperatures? Inconsistent wall thickness can also create differential shrinkage, as thicker sections cool more slowly than thin areas. Consider your material selection as well. Some engineered resins exhibit higher shrinkage rates or are more sensitive to processing conditions. Process adjustments often focus on pack pressure, hold time, and mold temperature. Increasing pack pressure and hold time ensures adequate material in the cavity as the part cools, while optimized mold temperature promotes uniform crystallization in semi-crystalline resins. Short Shots and Incomplete Fill When parts don't completely fill—leaving unfilled sections or thin areas—the investigation typically begins with material flow. Is the material reaching all areas of the cavity before it solidifies? Gate location plays a crucial role here. A gate positioned too far from thin-walled sections may allow material to freeze before complete fill. Flow analysis during the tool design phase helps identify potential issues, but sometimes real-world conditions reveal opportunities for optimization. Material temperature, injection speed, and machine tonnage all influence fill quality. Under-tonnage situations prevent adequate clamping force, allowing material to flash rather than fill properly. For low-volume, high-tonnage applications—where part geometry requires substantial clamping force—ensuring your press matches the application is essential. Surface Defects: Flow Lines, Sink Marks, and Blemishes Surface quality issues often trace back to material flow behavior and cooling dynamics. Flow lines appear when material enters the cavity at different temperatures, creating visible boundaries. Increasing material temperature and injection speed typically improves flow front uniformity. Sink marks occur when thick sections or ribs cool unevenly, pulling material inward as it contracts. Strategic use of gas-assisted injection molding can address this challenge by maintaining internal pressure during cooling, preventing surface depression without requiring excessive pack pressure. Surface blemishes might also indicate contamination, moisture in the resin, or venting issues. Proper material drying prevents moisture-related defects like splay or silver streaking. The Systematic Troubleshooting Process Rather than making multiple changes simultaneously, effective troubleshooting follows a disciplined approach: Document current conditions – Record all process parameters, material lot numbers, ambient conditions, and specific defect characteristics. Consistent documentation creates a baseline for comparison. Isolate variables – Change one parameter at a time, allowing several cycles to stabilize before evaluating results. This approach identifies which adjustments actually improve quality versus those that have no effect or make things worse. Verify material specifications – Confirm you're running the correct resin grade with proper drying and handling. Material inconsistencies can mimic process problems, sending troubleshooting efforts down the wrong path. Examine the tool – Inspect gates, vents, and cooling lines for wear, blockages, or damage. A poorly maintained tool creates problems no amount of process adjustment can overcome. Consider the machine – Verify shot size capacity, tonnage adequacy, and control system accuracy. Machines operating at the extreme edges of their capability struggle to deliver consistent quality. Prevention Through Engineering Excellence The most effective quality strategy isn't troubleshooting problems after they emerge—it's preventing them through thoughtful engineering upfront. Flow simulation reveals fill patterns, weld lines, and air trap locations. Material selection guided by application requirements ensures the resin matches the performance demands. Working with a partner who understands both the art and science of injection molding means fewer problem parts and more perfect components from the start. Moving Forward with Confidence Quality issues will emerge—that's the reality of manufacturing. But with systematic diagnostic approaches, technical expertise, and a commitment to continuous improvement, those challenges become opportunities for refinement rather than roadblocks to success. Whether you're troubleshooting current production or planning a new project, the key is partnering with a team that brings both technical depth and practical problem-solving experience to every component. At EnTech Plastics, we've built our reputation on turning complexity into capability. From our Corry, Pennsylvania facility, we deliver precision-engineered custom injection molding solutions for medical, industrial, trucking, and consumer applications—backed by decades of engineering excellence and technological innovation. Have a challenging part that's been causing headaches? Let's talk about transforming those problem parts into perfect components. Contact us today to discuss your project.

You've perfected your design. The 3D printed prototype fits flawlessly, functions exactly as intended, and even impresses the stakeholders. But now comes the reality check: transitioning from that successful 3D printed prototype to injection molded production parts isn't always a straight path forward. At EnTech Plastics, we regularly work with engineers who face this exact challenge. While 3D printing and injection molding both create plastic parts, they operate under fundamentally different rules—and what works brilliantly in additive manufacturing may not be possible to produce using injection molding. The Engineering Reality: Different Processes, Different Design Rules The freedom that makes 3D printing so appealing for prototyping—layer-by-layer construction with infinite geometric possibilities—becomes a constraint when you need to fill a mold cavity with molten plastic under high pressure and temperature. Draft Angles: The Hidden Design Requirement Your 3D printed part likely features perfectly vertical walls, sharp internal corners, and complex geometries built up layer by layer. But injection molding demands draft angles to allow the part to release cleanly from the mold. Those vertical walls that printed perfectly? They'll cause ejection problems, potential part damage, and premature tool wear in injection molding. Every vertical surface needs to be slightly tapered, and every internal corner needs a generous radius to facilitate material flow and part ejection. Wall Thickness: Consistency is Critical 3D printing builds support where needed, allowing for dramatic wall thickness variations within a single part. Injection molding, however, demands consistent wall thickness throughout the part to ensure uniform cooling, minimize warpage, and prevent sink marks or voids. Areas with thick sections will cool more slowly than thin sections, creating internal stresses that can lead to warpage, cracking, or dimensional instability. What appears as elegant design optimization in 3D printing creates significant quality issues in injection molding. Undercuts and Complex Geometries: The Mold Constraint Challenge Perhaps the most significant difference lies in geometric freedom. 3D printing can create virtually any shape—overhangs, internal cavities, interlocking parts, and complex undercuts—all in a single print job. Injection molding requires that every part feature can be formed by the opening and closing of mold halves. Complex undercuts require side actions, lifters, or collapsible cores—sophisticated tooling solutions that add significant cost and complexity to your custom injection molding project. These types of features can be accomplished if there are no design alternatives; in many cases, however, EnTech can provide Design for Manufacturability (DFM) analysis to provide design suggestions that will accomplish the intended function but with lower cost tooling. Gas-Assisted Injection Molding: Bridging the Design Gap Although conventional injection molding requires uniform wall thicknesses, EnTech also offers Gas Assist Injection Molding which accommodates designs that don’t have uniform wall thickness. Gas Assist Injection Molding allows for hollow sections, varying wall thicknesses, and complex internal geometries—bringing some of the design freedom of 3D printing into the injection molding realm. Gas assist injection molding can eliminate sink marks in thick sections, reduce material usage, and enable part consolidation that would otherwise require multiple components or assembly operations (see: https://entechplastics.com/gas-assist . Material Performance: Beyond Geometric Constraints The materials themselves behave differently between processes. Most 3D printing materials are designed for layer adhesion and printability, while engineered resins used in injection molding are optimized for flow characteristics, dimensional stability, and long-term performance. Your 3D printed prototype might use a material with completely different thermal, chemical, or mechanical properties than what you'll achieve with production-grade injection molding resins. This can affect everything from dimensional tolerances to environmental resistance. From Challenge to Solution Every transition from 3D printed prototype to injection molded production presents unique challenges. Whether you're dealing with complex geometries, demanding material requirements, or tight tolerance specifications, EnTech Plastics brings the engineering expertise and manufacturing capabilities to turn your design challenges into manufacturing successes. We specialize in the complex, the challenging, and the "difficult to run" parts that other molders struggle with. From custom injection molding and tool building to engineered resin selection and advanced manufacturing techniques, we have the resources and expertise to bridge the gap between your prototype vision and production reality. Contact our engineering team today to discuss your specific application. We'll work with you to understand your design intent, identify potential manufacturability challenges, and develop solutions that deliver both the performance you need and the production efficiency your business demands.

Tool transfer in injection molding—transferring production to a different facility—can go smoothly if done properly. Systematic planning and execution will ensure a smooth transition that maintains production continuity and part quality. Pre-Transfer Assessment: Building the Foundation Successful tool transfers begin with a comprehensive sharing of knowledge before the actual move takes place. Mold and Machine Compatibility Analysis : Start by documenting the mold specifications including dimensions, weight, tonnage requirements, and tie-bar spacing. This information will allow the new facility to determine what machines the transfer tools will be assigned to. Process Documentation Review : Whenever possible, gather whatever process parameters are available.This includes molding conditions, mold temperatures, injection pressures, and any special processing notes from operators. Though this data would be helpful, it is not essential if the existing supplier is not willing to share it. Auxiliary Systems Inventory : Catalog all supporting equipment including hot runners, temperature control units, material dryers, conveyors, and automation systems. Determine which components will transfer with the mold and which must be sourced at the destination. Quality Standards Assessment : Provide all quality specifications, inspection requirements, and acceptance criteria. The Quality Department at the new facility can then review, and clarify, this information with the customer. This will ensure that, as soon as production begins, the customer will receive parts that meet the required quality specifications. The more documentation available the easier the transfer process becomes. It should be stated however, that there have been many successful tool transfers with a minimal amount of knowledge being shared. Risk Mitigation and Contingency Planning To minimize the risk in any tool transfer program, the following strategies should be considered: Production Continuity Planning : Develop detailed schedules that minimize production disruption. Consider strategies such as building inventory buffers and scheduling transfers during planned maintenance windows. Quality Risk Assessment : Identify potential quality risks associated with the transfer and develop specific mitigation strategies. This includes understanding critical-to-quality characteristics and implementing enhanced monitoring during the initial production period. Emergency Response Procedures : Allow enough time in the transfer schedule for unexpected scenarios such as extended setup/startup times, or quality issues that prevent production startup. Industry-Specific Considerations Different market segments may present unique challenges that require specialized attention during tool migration. Some industry specific considerations are as follows: Automotive Applications : Focus on rigorous dimensional validation, material traceability, and compliance with IATF 16949 requirements. Plan for capability studies and potential PPAP (Production Part Approval Process) submissions. Medical Device Manufacturing : Emphasize contamination control, process validation requirements, and FDA compliance considerations. Consumer Products : Balance quality requirements with cost considerations, focusing on consistent appearance, functionality, and cycle time optimization to maintain competitive positioning. Conclusion Successful injection molding tool transfer programs require a comprehensive approach that addresses the unique technical, quality, and operational challenges of plastics manufacturing. While each transfer presents specific challenges, organizations that develop systematic capabilities and follow proven practices will achieve significantly better outcomes in terms of downtime, quality, and cost. The key to success lies in recognizing that tooling transfers are not simply a matter of moving equipment, but rather a process that involves machine compatibility, process optimization, quality validation, and regulatory compliance. By addressing all these elements systematically and maintaining focus on part quality and production efficiency, manufacturers can transform tool transfers from sources of risk and disruption into opportunities for process improvement and operational excellence. Remember that successful tool transfers ultimately enable production teams to manufacture high-quality parts efficiently and consistently, regardless of which machine or facility is used. Keep this objective at the center of your transfer planning, and the technical and logistical challenges become much more manageable. Contact EnTech Plastics today to discuss your project and how we can assist with a smooth transition. Don't leave your tool transfer to chance. Make sure everything goes smoothly with our handy checklist. Grab your free tool transfer checklist now.

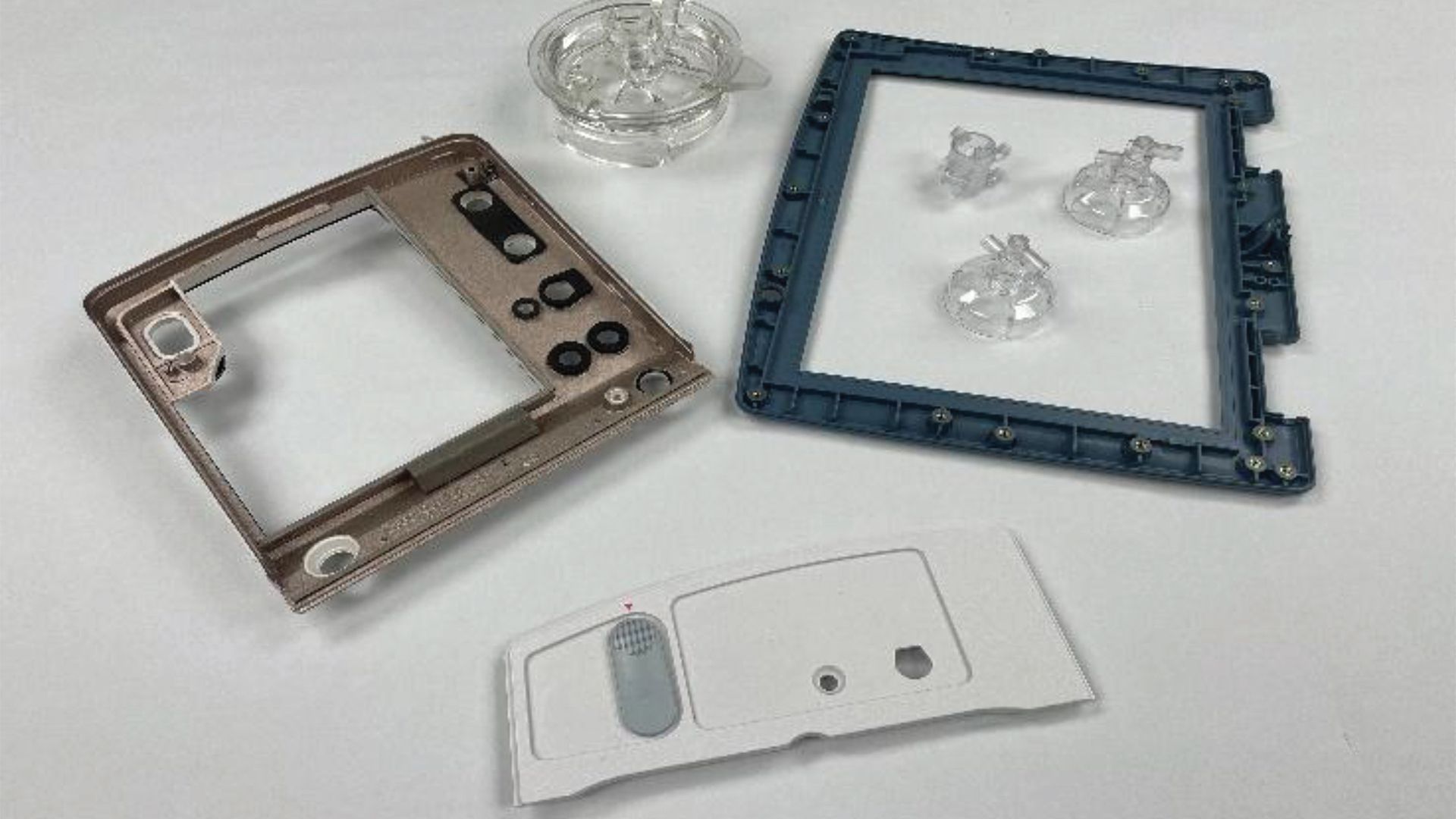

When bringing a new product to market, manufacturers face critical decisions about which production methods to use at different stages of development. Two approaches that often come up in discussions are low volume injection molding and rapid prototyping. While both serve important roles in product development, they address fundamentally different needs and offer distinct advantages depending on your specific requirements. Understanding the differences between these manufacturing approaches can save significant time, money, and resources while ensuring your product reaches the market successfully. What is Rapid Prototyping? Rapid prototyping encompasses various additive manufacturing technologies designed to quickly create physical models of parts and products directly from digital designs. The primary purpose of rapid prototyping is to enable fast iteration during the design phase. Engineers and designers can test form, fit, and basic function without the time and expense of creating production tooling. Changes can be made quickly by simply modifying the digital file and printing a new version. What is Low Volume Injection Molding? Low volume injection molding uses the same fundamental process as traditional high-volume injection molding but is optimized for smaller production runs , typically ranging from 100 to 10,000 parts. This approach uses simplified tooling, often made from aluminum rather than steel, and may employ rapid tooling techniques to reduce lead times and costs. The goal is to produce parts that meet the part specifications while keeping tooling investments reasonable for smaller quantities. This makes it an attractive option for products with naturally low volume requirements. Key Differences Between the Two Approaches Purpose and Development Stage Rapid prototyping primarily serves the design verification phase. It's ideal for testing concepts, validating designs, and communicating ideas to stakeholders. The focus is on speed and iteration rather than production-ready parts. Low volume injection molding, however, is used when you've moved beyond concept validation and need parts for market testing, pilot production, or limited commercial release. Material Properties and Quality This represents perhaps the most significant difference between the two approaches. Rapid prototyping materials, while continuously improving, still have limitations compared to production injection molding resins, such as: Anisotropic properties (different strength in different directions) Lack of chemical resistance Lack of UV stability Low volume injection molding uses the same materials available for high-volume production, including engineering plastics with specific properties like flame retardancy, chemical resistance, or biocompatibility. Parts produced through low volume injection molding exhibit consistent properties throughout and meet the required performance characteristics but they are produced in small-volume production runs. Surface Finish and Aesthetics Rapid prototyping typically produces parts with visible layer lines or surface textures that may require post-processing to achieve acceptable aesthetics. While techniques exist to improve surface finish, they add time and cost to the process. Low volume injection molded parts can achieve surface finishes ranging from textured to mirror-like, depending on the mold design. The surface quality is consistent and repeatable, making it suitable for customer-facing applications or parts requiring specific aesthetic standards. Dimensional Accuracy and Tolerances Most rapid prototyping technologies can achieve reasonable dimensional accuracy for conceptual work, but may struggle with tight tolerances required for functional assemblies. Factors like material shrinkage, warping, and support structure placement can affect final dimensions. Low volume injection molding provide much tighter tolerances depending on part geometry and material. This precision is crucial for parts that must interface with other components or meet specific functional requirements. Lead Times and Flexibility Rapid prototyping excels in speed for initial parts. Simple components can be produced within hours or days of design completion. Changes are easily accommodated by modifying the digital file. Low volume injection molding requires time for tool design and manufacturing, typically several weeks depending on complexity. However, once tooling is complete, parts can be produced quickly. Making the Right Choice for Your Project While rapid prototyping has its place in early concept validation, low volume injection molding emerges as the clear winner when you need parts that truly perform. The superior material properties, consistent quality, and production-ready performance make it the smart choice for initial low volume production runs of functional parts.. The initial tooling investment quickly pays for itself through lower per-part costs, especially when you factor in the time saved from not having to reprocess parts due to material limitations or quality issues. More importantly, low volume injection molding gives you confidence that your parts will perform exactly as intended in real-world applications. When you're ready to move beyond basic prototypes and create parts that meet your actual performance requirements, low volume injection molding provides the reliability, quality, and cost-effectiveness that rapid prototyping simply cannot match. Don't let the allure of "quick and cheap" prototyping derail your product's success when production-quality parts are within reach. Ready to Experience the Low Volume Injection Molding Advantage? EnTech Plastics specializes in low volume custom injection molding solutions ; our experienced team can help you evaluate your project requirements and determine the most cost-effective approach for your specific needs. With state-of-the-art equipment and decades of expertise, we deliver production-quality parts with the flexibility and speed your project demands. Contact EnTech Plastics today to discuss how low volume injection molding can accelerate your product development and ensure market-ready performance from day one.

When embarking on an injection molding project, choosing the right material is one of the most critical decisions you’ll make. The material you select will directly impact your product’s performance, durability, cost-effectiveness, and market success. This is where comprehensive materials testing and evaluation becomes invaluable—and where EnTech Plastics can serve as your trusted partner in navigating these complex decisions. Why Materials Testing & Evaluation Matters Material selection isn’t a one-size-fits-all process. Every injection molding project has unique requirements based on the intended application, operating environment, regulatory standards, and cost constraints. Without proper testing and evaluation, you risk costly production delays, product failures, or over-engineering that unnecessarily inflates costs. Materials testing provides the data-driven insights needed to make informed decisions, ensuring your chosen material will perform reliably throughout your product’s lifecycle while meeting all necessary specifications and standards. Key Considerations in Materials Testing & Evaluation Mechanical Properties Understanding how your material will behave under stress is fundamental. Key mechanical properties to evaluate include tensile strength, flexural modulus, impact resistance, and fatigue performance. These properties determine whether your part can withstand the forces it will encounter during use. Consider a medical device component that requires both flexibility and strength, or an automotive part that must maintain integrity under temperature cycling and vibration. Each application demands specific mechanical characteristics that must be verified through testing. Thermal Performance Temperature requirements significantly influence material selection. You’ll need to assess heat deflection temperature, continuous use temperature, thermal expansion coefficients, and thermal conductivity. Understanding how your material behaves across its operating temperature range prevents warping, dimensional instability, and premature failure. Chemical Resistance Will your product be exposed to chemicals, UV radiation, or environmental stressors? Chemical resistance testing reveals how materials respond to solvents, acids, bases, and other substances they may encounter. This is particularly critical for applications in healthcare, automotive, or industrial environments. Processing Characteristics Even if a material meets performance requirements, it must be processable in your specific injection molding setup. Flow characteristics, mold shrinkage, cycle time requirements, and processing temperature windows all affect manufacturability and final part quality. Regulatory Compliance Many industries require materials to meet specific standards—FDA approval for medical devices, UL ratings for electrical components, or automotive specifications for vehicle parts. Testing ensures compliance before production begins. Cost Optimization Materials testing helps identify the most cost-effective solution that meets performance requirements. Sometimes, a less expensive material with adequate properties outperforms premium options for specific applications. How EnTech Plastics Supports Your Materials Journey Expert Material Selection Guidance EnTech Plastics brings decades of experience to your material selection process. Our team understands the nuances of different polymer families and can recommend materials that align with your performance requirements and budget constraints. We consider your application’s unique demands and suggest materials you might not have considered. Testing-Backed Recommendations Our material recommendations are informed by extensive testing conducted on various materials across different applications. From basic mechanical properties to specialized characteristics like environmental stress crack resistance and long-term aging performance, we review published resin specification data and consult with engineering teams at the resin producers to ensure the materials being considered have been validated for similar applications. Application-Specific Expertise Our experience spans multiple industries, from medical devices to automotive components to consumer products. This broad expertise allows us to anticipate potential challenges and recommend proven solutions based on similar applications. Making Data-Driven Decisions The goal of materials testing isn't to find the “perfect” material—it’s to identify the optimal balance of properties, processability, and cost for your specific application. This data-driven approach minimizes risk and maximizes the likelihood of project success. Consider the alternative: choosing materials based on assumptions or limited information. This approach often leads to costly redesigns, production delays, or field failures that could have been prevented through proper upfront evaluation. Beyond Initial Selection: Ongoing Support Successful injection molding projects begin with thoughtful material selection backed by comprehensive testing and evaluation. Whether you’re developing a new product or looking to optimize an existing one, the expertise and resources available through EnTech Plastics can help ensure your material choices support your project’s success. Ready to discuss your material evaluation needs? Our team of experts is prepared to help you navigate the complexities of material selection to provide the insights you need for confident decision-making. Contact EnTech Plastics today to learn how our materials expertise can support your next injection molding project. Together, we'll ensure your material choices provide the foundation for product success.

When it comes to manufacturing plastic parts, two of the most widely used processes are injection molding and compression molding. While both techniques shape materials using heat and pressure, they differ significantly in their approach, capabilities, and ideal applications. Understanding these differences is crucial for manufacturers, designers, and engineers when selecting the optimal process for their specific needs. What is Injection Molding? Injection molding is a manufacturing process where heated, molten material (typically thermoplastic) is injected under high pressure into a closed mold cavity. The process begins with plastic pellets or granules being fed into a heated barrel where they're melted and mixed by a rotating screw. Once the material reaches the proper temperature and consistency, it's injected at high pressure through a nozzle into the mold cavity. The mold is then cooled, allowing the material within to solidify, taking the shape of the mold before being ejected as a finished part. What is Compression Molding? Compression molding is a forming process where a pre-measured amount of material (often thermosetting plastics, composites, or rubber) is placed directly into an open, heated mold cavity. The mold is then closed under pressure, causing the material to conform to the mold shape while curing or vulcanizing. The process starts with a "charge" of material—typically in powder, pellet, or preform shape—being placed in the lower half of a heated mold. The upper half of the mold is then pressed down with significant force, distributing the material throughout the cavity. The combination of heat and pressure causes chemical cross-linking in thermosetting materials, creating the final cured part. Key Differences: Injection Molding vs Compression Molding Speed and Cycle Time Injection Molding typically offers faster cycle times, especially for smaller parts. Once the mold is filled, cooling happens relatively quickly, and parts can be ejected in seconds to minutes. Compression Molding generally requires longer cycle times due to the curing process needed for thermosetting materials. Parts may need to remain in the mold for several minutes to ensure complete curing. Material Compatibility Injection Molding works best with thermoplastics that can be melted and re-solidified multiple times. Common materials include polyethylene, polypropylene, ABS, nylon, and polycarbonate. Compression Molding is ideal for thermosetting materials that undergo irreversible chemical changes when heated. This includes materials like phenolic resins, epoxies, silicones, and rubber compounds. It's also excellent for fiber-reinforced composites. Part Complexity and Precision Injection Molding excels at producing complex geometries with tight tolerances, intricate details, and thin walls. The high-pressure injection allows material to flow into fine features and sharp corners. Compression Molding is better suited for simpler shapes and is particularly effective for large, thick-walled parts. While precision is good, it may not match the tight tolerances achievable with injection molding. Tooling and Setup Costs Injection Molding typically requires higher initial tooling costs due to the complexity of the molds, which must withstand high pressures and include sophisticated cooling and ejection systems. Compression Molding generally involves lower tooling costs since the molds are simpler in design and don't require the same level of precision machining or cooling systems. Typical Applications Injection Molding Applications Industrial Devices: Leveraging benefits such as durability, cost-effectiveness, design flexibility, and lightweight, injection molded plastics find extensive functional applications in various industrial sectors. Medical Devices: Diagnostic equipment housings, Medical equipment components, Syringes, IV components, and surgical instruments demand the cleanliness and precision of injection molding. Consumer Electronics : Phone cases, computer housings, connectors, and small electronic components require the tight tolerances and smooth finishes that injection molding provides. Automotive Industry : Dashboard components, interior trim, bumpers, light housings, and under-hood components benefit from injection molding's precision and efficiency. Packaging : Bottle caps, containers, lids, and disposable items are mass-produced efficiently using injection molding. Toys and Recreation : Action figures, building blocks, sporting goods, and recreational equipment benefit from injection molding's ability to create detailed, colorful parts. Compression Molding Applications Aerospace and Defense : Composite panels, radomes, structural components, and heat shields utilize compression molding's ability to process advanced composite materials. Automotive Industry : Heavy-duty components like brake pads, gaskets, electrical insulators, and composite body panels are well-suited to compression molding. Electrical and Electronics : High-voltage insulators, electrical switchgear housings, and components requiring excellent electrical properties are often compression molded. Industrial Equipment : Valve seats, pump components, industrial gaskets, and chemical-resistant parts benefit from compression molding's material versatility. Kitchen and Appliance : Heat-resistant handles, cookware components, and appliance parts that require durability and heat resistance are ideal for compression molding. Ready to Bring Your Project to Life? Both injection molding and compression molding serve crucial roles in modern manufacturing. Injection molding excels in production of complex thermoplastic parts with excellent precision, while compression molding is the preferred choice for thermosetting materials, composites, and applications requiring specific material properties. Understanding the strengths and limitations of each process enables manufacturers to make informed decisions that optimize cost, quality, and performance for their specific applications. As both technologies continue to advance, they will remain essential tools in the manufacturing toolkit, each serving distinct market needs and applications. Looking for a precision-driven partner for your next plastic manufacturing project? At EnTech Plastics, we specialize in custom injection molding—delivering high-quality, cost-effective solutions for even the most complex part designs. Whether you're developing components for industrial goods or the medical, automotive, or consumer goods industries, our expert team is ready to help turn your concept into reality. Contact us today to discuss your project requirements.

Low volume injection molding fills the critical gap between prototyping and mass production, providing engineers with a versatile manufacturing solution for production runs typically ranging from 100 to 10,000 parts. This guide explores the essential aspects of this process, helping engineers make informed decisions when specifying and designing for low volume injection molding. As manufacturing demands continue to evolve toward more agile and responsive production methods, understanding the capabilities and limitations of low volume injection molding becomes increasingly valuable for today's engineering professionals. Understanding Low Volume Injection Molding Definition and Scope Low volume injection molding typically refers to production runs of smaller quantities than traditional mass production. These can range from approximately 100-1,000 parts for prototyping and early-stage testing, 1,000-5,000 parts for pilot production or niche markets, and up to 10,000 parts for short production runs. The exact definition of "low volume" varies by industry and application, but generally refers to quantities that don't justify the high investment of hardened steel tooling used in mass production. When to Choose Low Volume Injection Molding Low volume injection molding serves multiple purposes across the product development lifecycle. It excels in functional prototyping scenarios where engineers need multiple identical prototypes for testing and validation using actual production-grade materials. This provides more accurate test results than other prototyping methods that might use different materials or manufacturing processes. It also serves as an effective bridge production solution, filling the gap between initial prototyping and full-scale manufacturing. This approach allows companies to enter the market while traditional high-volume tooling is being developed, potentially generating revenue earlier in the product lifecycle. Market testing represents another valuable application, where companies can produce limited quantities to gauge market response before committing significant resources to mass production infrastructure. For specialized components with limited market demand, low volume injection molding often provides the only economically viable manufacturing path. Many manufacturers also leverage this approach for supply chain optimization, producing parts on-demand to reduce inventory costs and effectively manage demand volatility. This just-in-time manufacturing approach can significantly reduce warehousing costs and obsolescence risks. Tooling Options for Low Volume Production Aluminum Molds Aluminum molds represent the most common tooling solution for low volume injection molding due to their excellent balance of cost, speed, and performance. Compared to traditional steel molds used in high-volume production, aluminum tooling offers 40-60% lower costs and significantly faster lead times, typically 2-4 weeks versus the 4-8 weeks required for steel tooling. The superior thermal conductivity of aluminum—conducting heat approximately five times faster than steel—results in shorter cycle times during production. This thermal efficiency allows for quicker cooling of molded parts, reducing overall production time and increasing throughput. Additionally, aluminum's softer nature makes it easier to machine, further reducing tooling costs and lead time. While not as durable as steel, aluminum molds provide sufficient durability for low to medium production volumes, typically handling between 10,000 and 100,000 shots depending on the material being molded and the complexity of the part geometry. This makes them an ideal choice for most low-volume applications where tooling cost and lead time are critical factors. 3D Printed Molds For very small production runs or rapid prototyping needs, 3D printed molds offer an innovative and increasingly viable solution. These molds can be produced at significantly lower costs, often between $100-$500 for simple geometries, and with extremely fast turnaround times measured in days rather than weeks. This approach enables engineers to quickly iterate on designs without the financial burden of traditional tooling. 3D printed molds are most effective for producing limited quantities, typically between 50-200 parts, depending on the material being molded and the complexity of the part. They work particularly well for proof-of-concept models and initial market samples where dimensional precision is less critical than speed to market. However, these molds do come with significant limitations that engineers must consider. Their limited durability restricts them to lower shot counts, they're generally restricted to simpler geometries and less demanding materials, and they provide lower dimensional accuracy compared to metal molds. Temperature and pressure limitations also constrain the range of materials that can be effectively molded with 3D printed tooling. Soft Tooling Soft tooling using materials like silicone or urethane provides another option for short production runs. These molds can be produced at lower costs than aluminum tooling and with quick turnaround times, making them suitable for projects with extremely tight timelines or budget constraints. These tools perform best with parts featuring relatively simple geometries and work well for prototyping and very short production runs, typically under 500 shots. The flexible nature of these materials can sometimes allow for parts with features that might be challenging with rigid tooling, such as limited undercuts. Engineers should be aware that soft tooling comes with significant limitations, including restricted material compatibility, less precise tolerances, and a substantially shorter lifespan compared to metal tooling. These factors make soft tooling most appropriate for early development phases rather than ongoing production. DME MUD Inserts Some manufacturers use MUD (Master Unit Die) inserts for lower volume tooling as a cost-effective alternative to full custom molds. This universal mount system uses less steel and fewer off-the-shelf components to build the mold, resulting in significant savings on tooling costs. MUD inserts offer faster changeovers for multiple parts, making them particularly suitable for part families or products with multiple variants. The ability to reuse the base while changing only the inserts provides both economic and time advantages for appropriate applications. This approach works best for smaller parts that fit within the standardized frame sizes of the MUD system. While not suitable for all applications, MUD inserts represent a valuable intermediate option between fully custom tooling and more temporary solutions like 3D printed molds. Material Selection Many thermoplastics used in high-volume injection molding are also well-suited for low-volume applications, offering engineers a broad range of options to meet specific project needs. However, successful material selection in low-volume production requires a strategic balance of several interrelated factors. The process should begin with functional requirements—ensuring that the material’s mechanical, thermal, electrical, and chemical properties align with the application. Cost is equally important, not just in terms of raw material price, but also processing conditions and cycle times, which can offset lower per-pound costs. Tooling compatibility is another key factor, especially when using aluminum molds common in low-volume runs. Abrasive materials, such as those with glass fiber reinforcement, can significantly reduce tool life and impact cost-effectiveness. Engineers should also account for post-processing needs like painting, texturing, or assembly. Selecting materials that meet aesthetic and performance standards straight out of the mold can streamline production and reduce lead times. Finally, environmental exposure—such as temperature extremes, chemicals, UV radiation, and moisture—must be considered to ensure long-term material performance. Choosing a material with the right resistance profile is critical to product durability and reliability. Design Considerations Wall Thickness - Maintaining a uniform wall thickness is essential to prevent molding defects like warping, sink marks, and internal stresses caused by uneven cooling. In low-volume production, where tooling revisions can be costly, getting wall thickness right the first time is especially important. Part Finish - Specifying the correct surface finish is key to balancing cost and performance. Highly polished finishes significantly raise tooling expenses due to the labor-intensive polishing process. For non-visible components, an as-machined finish is a cost-effective option. For moderate cosmetic needs, bead-blast texture provides a cleaner look without the high cost of polishing. Gate Location and Design - Gate placement directly affects how molten plastic flows through the mold, influencing both the quality and appearance of the part. Proper gate location ensures uniform filling and reduces the risk of weld lines or voids. Since gates leave marks, they should be positioned in low-visibility areas or where post-processing can easily remove marks or blemishes. Parting Lines - Parting lines—where mold halves meet—leave visible seams on finished parts and must be planned carefully. Avoid placing parting lines on functional or highly visible surfaces, such as sealing areas or product front faces. Instead, these lines should align with natural edges or surface transitions to minimize their appearance. Leveraging Low Volume Injection Molding Low volume injection molding offers engineers a versatile and cost-effective solution for producing high-quality plastic parts in quantities that bridge the gap between prototyping and mass production. By understanding the unique considerations, tooling options, and design principles outlined in this guide, engineers can successfully leverage this manufacturing method to accelerate product development, optimize costs, and bring innovative products to market more efficiently. EnTech Plastics specializes in low volume injection molding solutions tailored to your specific engineering challenges. Contact EnTech Plastics today to discuss your next engineering project and discover how our low volume injection molding capabilities can help you bring innovative products to market faster and more efficiently.